Continuous drying and dewatering systems as well as spin-dryers with batch loading

The drying systems are used to dry lettuce, herbs, vegetables and fruit. In addition, the machines can be used to shorten the draining times of canned (e.g. mushrooms, pickles) or defrosted products. Other foods such as crab, caviar (substitute) or sesame seeds can also be dewatered. All solutions can be integrated into processing lines. Two main procedures are used to dry the products:

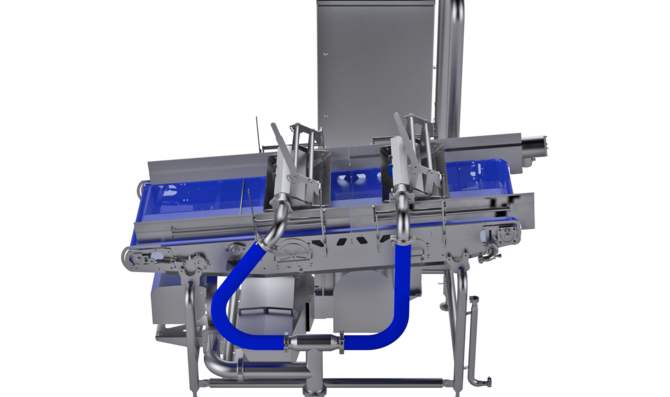

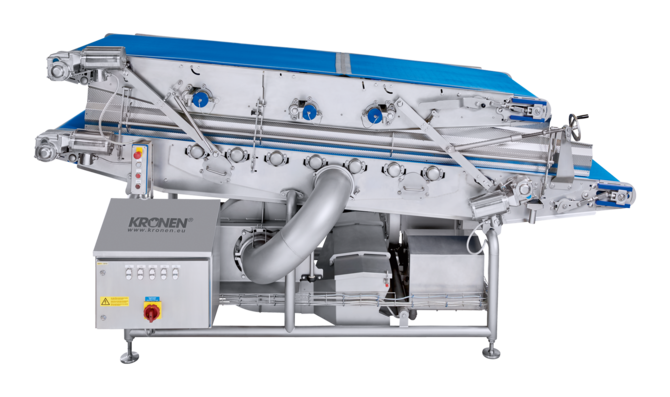

- The centrifuges spin-dry the product. The KS series is comprised of smaller spin-dryers for manual batch loading. The K850 and K650 drying systems are large centrifuges for continuous, fully automatic drying and for high capacities. All centrifuges are suitable for versatile applications.

- In the belt dewatering systems, the product is continuously dewatered using air blowers. They are usually combined with an additional drying solution. Solutions are available for whole fruits and vegetables or for light, leafy products.

In addition to the large dryers for the food industry and the smaller spin-dryers, we also offer a dewatering press that removes water from pickled or thawed products, for example for the production of cold cuts or vegan and non-vegan fillings.