The well-established cutting machine for high production capacities has been optimized with regard to hygienic design and the cost-saving and resource-conserving replacement of two important spare parts.

KRONEN GmbH recently made improvements to its GS 20 belt cutting machine to achieve better hygiene, improved operational safety and reduced costs for customers when it comes to purchasing important spare parts. The well-established machine is a classic product in KRONEN’s machine portfolio and processes fruit, vegetables, salad leaves and a multitude of other extremely varied food products with a capacity of up to 4,000 kg per hour.

To ensure that the cutting machine achieves perfect cutting results on a long-term basis, parts such as the Roller bearing support holder for the transport belt and downholder belt need to be replaced after a certain amount of time. Up until now, this process has required the blocks to be replaced in their entirety. Now, however, the Roller bearing support holders have been revised so that only the bearing axle support bars have to be replaced, thus achieving a significant cost reduction. These new versions are backward compatible. As a result, a single purchase of the new spare parts even allows existing models to benefit from the long-term savings now available.

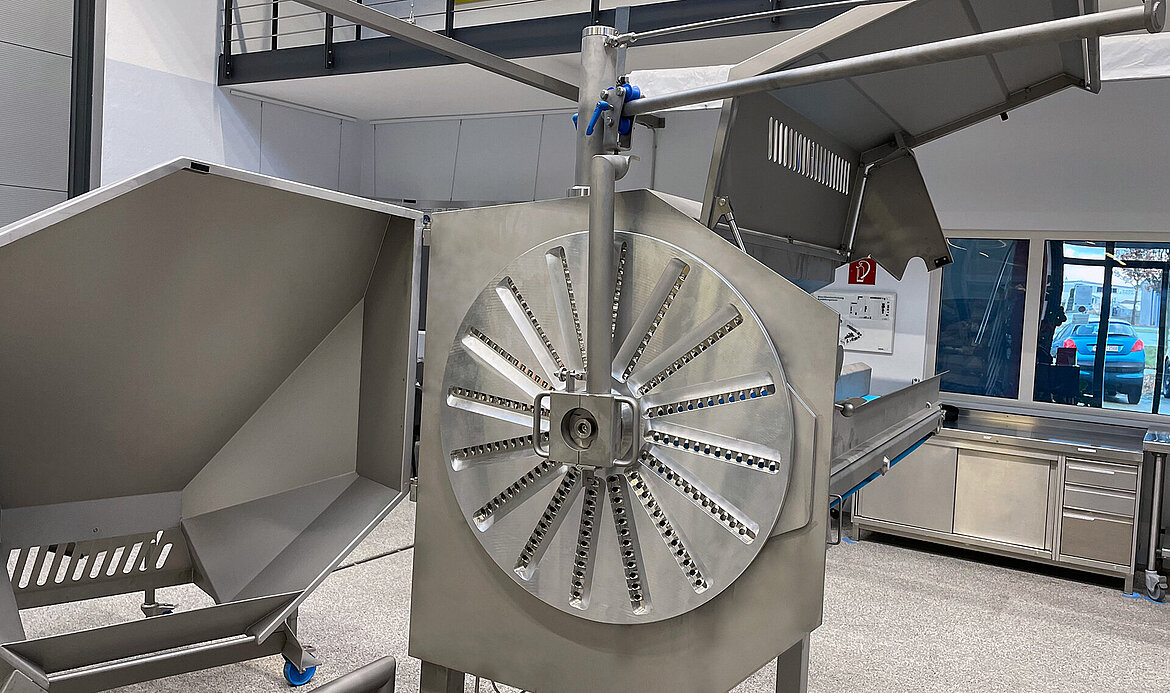

In terms of the machine’s hygienic design, KRONEN has reduced the number of screw fastenings for the belt and knife box, improved the product discharge and redesigned the blade flange. It has also upgraded the swivel arm, an optional accessory of the GS 20 for easier replacement of the cutting disks, to eliminate hollow spaces and reduce the number of screw fastenings. Furthermore, a new function for fixing the carriage improves operational safety by preventing the swivel arm from being nudged unintentionally when the machine is moved.

The GS 20 is characterized by its high performance and processing quality, which guarantees precisely and gently cut products. It has been used by customers in the field of industrial food processing all over the globe for many years. As a multifunctional machine that can be used flexibly to cut, pull, shred and grate a multitude of products, the GS 20 is a reliable, flexible solution for the food industry.

“It is important that we always keep learning, developing and making progress rather than simply settling for what we have already achieved. I think that is what truly defines our team at KRONEN,” states Eric Lefebvre, Managing Director and Technical Director at KRONEN. “For 40 years, our contact with the industry, the world of research and groups of experts such as the EHEDG has helped us gain new insights in the areas of technology and hygienic design and to implement this knowledge in our development activities. Our aim is to develop solutions that will benefit our customers, and the upgrades to the GS 20 are another prime example of how we achieve this.”.

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product portfolio of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging.

KRONEN additionally offers machines for the processing of meat and fish, special vegan products, baked goods and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representatives in over 80 countries worldwide and supplies its products to more than 120 nations all over the globe.

With more than 45 years of experience in food technology, KRONEN prides itself on its quality awareness and constantly strives to achieve the best possible solutions in its day-to-day work. The machine manufacturer focuses on taking a sustainable, holistic approach toward the hygienic, reliable and resource-friendly production of fresh foods. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.

You can find a selection of images below (click on the right mouse button and select “Save image as” to download).

Do you require more or other material? We are happy to help! Feel free to contact us here: presse@kronen.eu, T +49 7854 9646-160 / -161.