Bell peppers are one of the most commonly processed vegetables on a global level, for example for use in salads, grilled goods, frozen foods or as a filling ingredient in convenience products. The processing activities involved in such products require efficient procedures and consistent cutting quality, for example when removing the stalk and seeds or cutting bell peppers into precisely portioned strips or cubes.

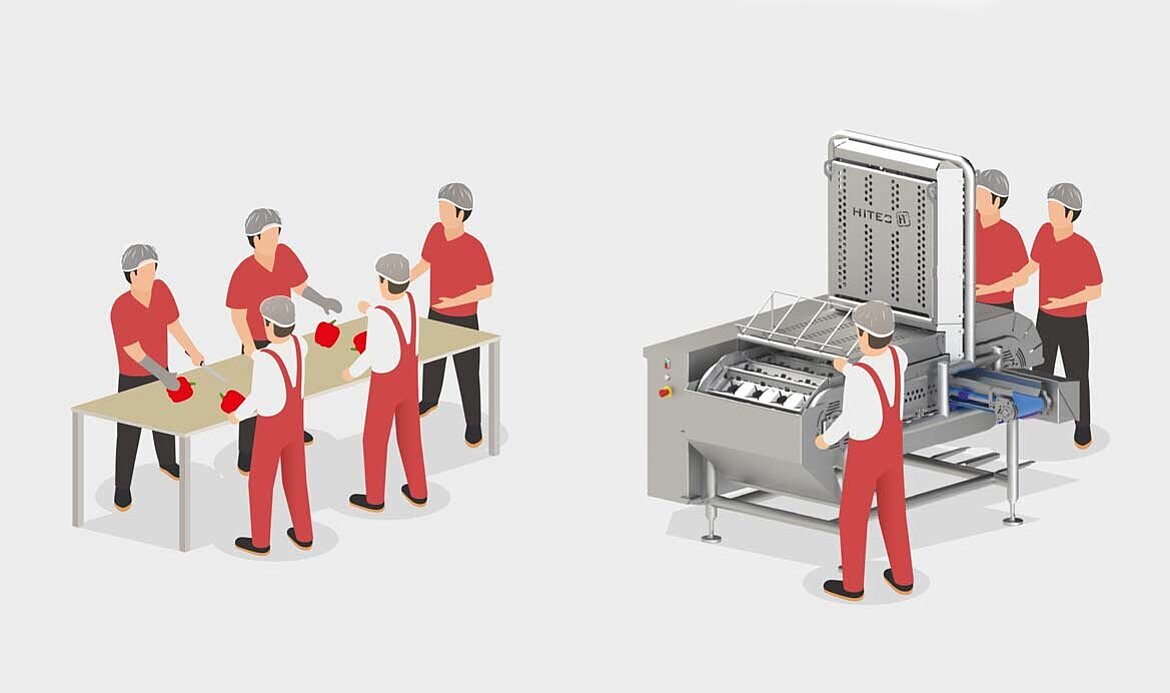

Solutions by KRONEN and its partners – for example automatic washing and cutting machines and special systems for coring and dividing – are used for such processing activities in locations worldwide, helping to achieve optimized processes and a constantly high yield.

Industrial bell pepper processing: gentle, efficient and precise

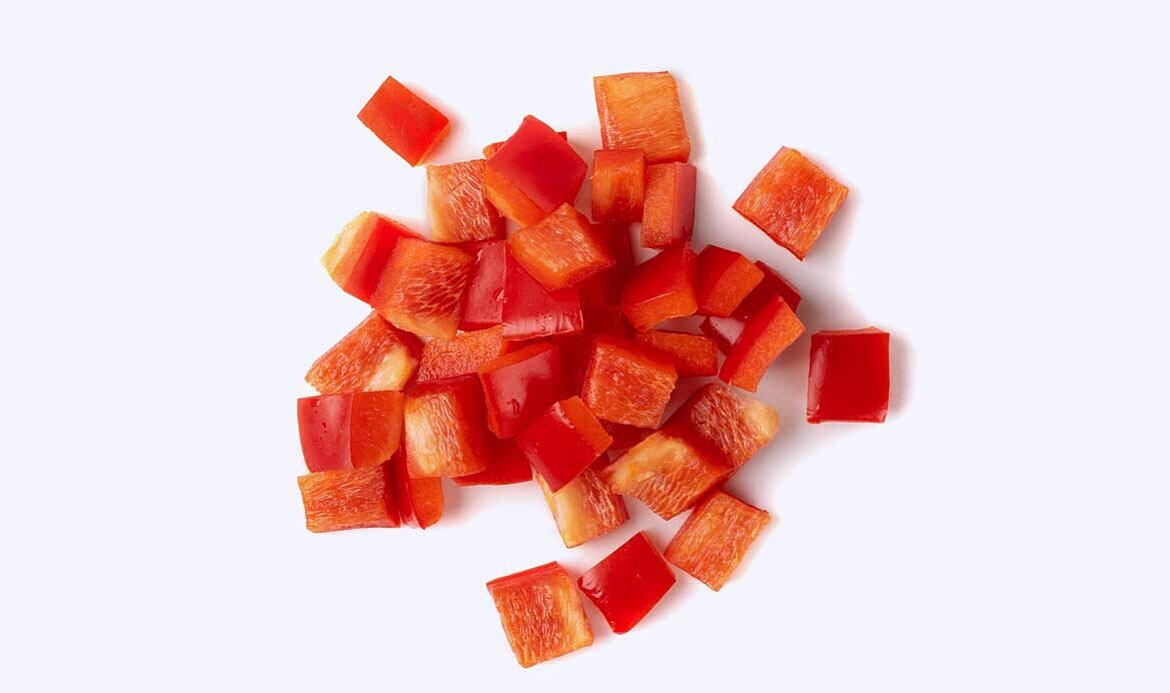

Be it halved, quartered or cut into even strips and cubes, the KRONEN machines process fresh or prepared bell peppers both gently and precisely – with high capacities and a reduced loss rate. The machines used for such tasks include the PDS4L pepper coring and dividing machine, which can core, then halve or quarter up to 3,360 bell peppers per hour in a semi-automatic process, and the GS 10-2 or GS 20 belt cutting machines, which provide precisely cut strips or cubes.

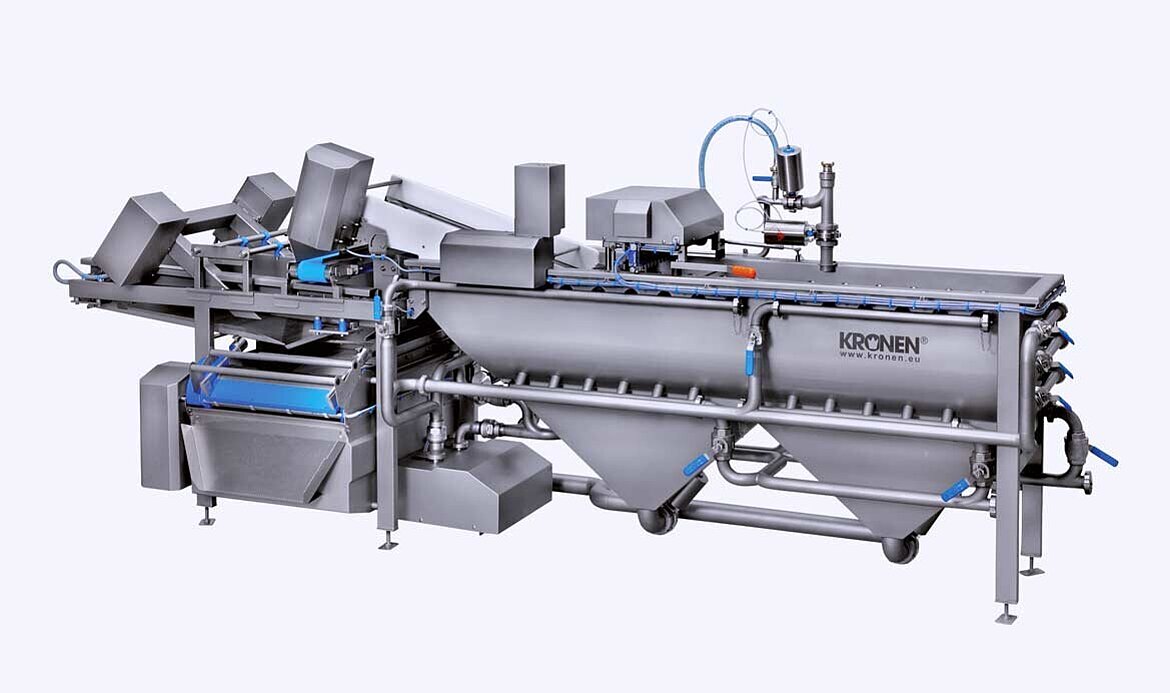

Furthermore, the GEWA 3850V PLUS washing machine was developed especially for bell peppers and can clean and sort up to 1,200 kg of cored, cut bell peppers per hour in a particularly gentle and rapid process.

Hygienic and flexible – machine solutions for a perfect end product

Regular cleaning is particularly important when processing bell peppers, especially in the case of moist cut products. The KRONEN machines feature an optimized hygienic design that enables them to be cleaned rapidly and without any tools, thus reducing downtime and ensuring maximum hygiene standards.

The versatility of the systems also enables them to be used flexibly for other products such as zucchini, tomatoes, eggplant and many more when bell peppers are no longer in season. The modular design of most KRONEN systems enables them to be easily adapted to meet changing requirements.

Complete solutions for bell pepper processing

From washing to coring and right through to cutting, KRONEN offers a wide range of machines and complete solutions for the efficient processing of bell peppers.

Both as stand-alone machines and as part of processing lines for fruit, vegetables and salad leaves, the systems provide quality, cost-effectiveness and optimized production procedures tailored to meet the specific demands of the industry for customers all over the globe.