Drying system for processing lines: drying up to 1,500 kg of vegetables and salad leaves efficiently and hygienically

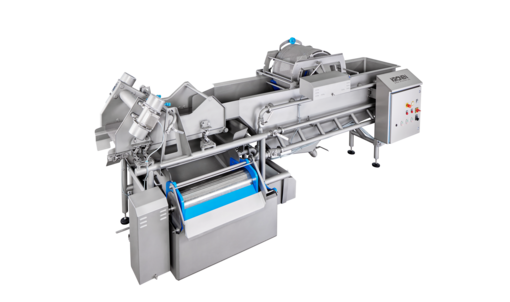

The K1040H is a fully automated drying system for gently spin-drying vegetables, salad leaves and vegan products. The machine can be optimally integrated into continuous processing lines and processes products that are discharged directly from a washing machine onto the infeed belt.

The K1040H is suitable for both light leafy vegetables such as baby leaf lettuce, salad mixes, herbs and spinach and heavier cut vegetables like diced onion and carrot sticks, as well as pickles and vegan products.

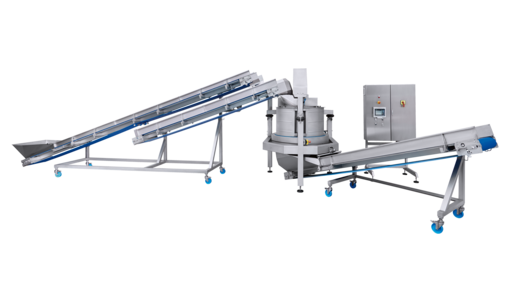

The wet product is discharged from a washing machine (transfer area width max. 500 mm) onto the infeed belt of the K1040H. The buffer function is integrated into the infeed belt for continuous processing, although the centrifuge itself dries the product in batches. The well-thought-out arrangement of the infeed belt and the drying system ensures that the product is evenly fed into and distributed in the drum. The large drum surface area ensures especially gentle drying results. Thanks to the high centrifugal force, spin-drying times are reduced compared to smaller centrifuges such as the KS-100 PLUS. An optional volume control function can also be used to optimize the product infeed quantity.

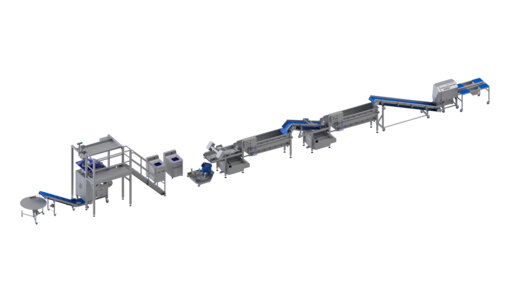

The water that adheres to the surface of the washed product is removed by the acceleration of the spinning drum to the set speed. At the end of the drying cycle, the spin-dried product is gently blown out of the machine into 200 l standard containers or onto the optional discharge belt. The dried product can then be transferred to an automatic weighing and packaging line.

Depending on the product and the quantity processed, step switches can be used to set the spinning time and speed to one of four different levels. This makes operating the machine particularly user-friendly. The individual capacity depends on the product, spinning speed and spinning time.

KRONEN’s K650 and K850 drying systems are high-performance alternatives for higher processing capacities of up to 5,000 kg per hour.