Completion of the project following the development of a new washing machine and successful tests with plasma-based disinfection technology

In November, the research project SPLASH, which was funded by the German Federal Ministry of Food and Agriculture (BMEL), was officially brought to a close. Prior to this, the results of the project had already been presented to visitors at the KRONEN Customer Day: The twelve-month-long test phase, which used the newly developed HEWA washing machine in combination with the plasma washing process in an industrial setting, achieved positive results. Against this background, the partners from the Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB Potsdam), the company Gartenfrisch Jung GmbH, the Leibniz Institute for Plasma Research and Technology (INP Greifswald) and KRONEN GmbH will continue to work together to scale the solution to meet various industrial requirements in the future.

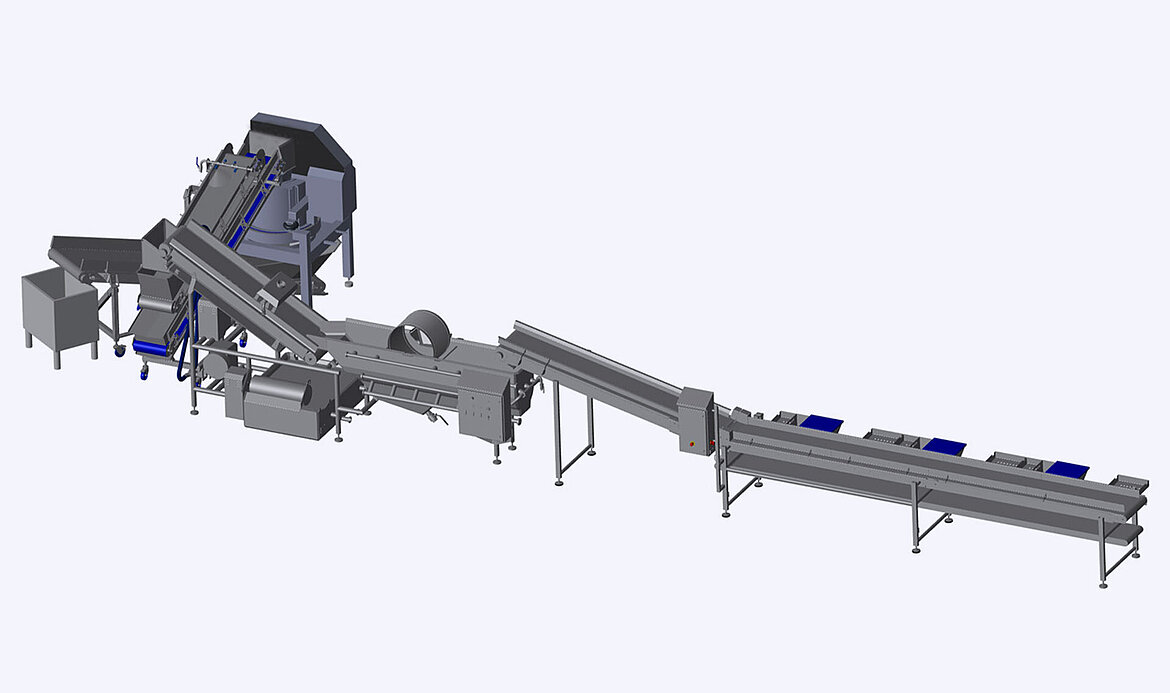

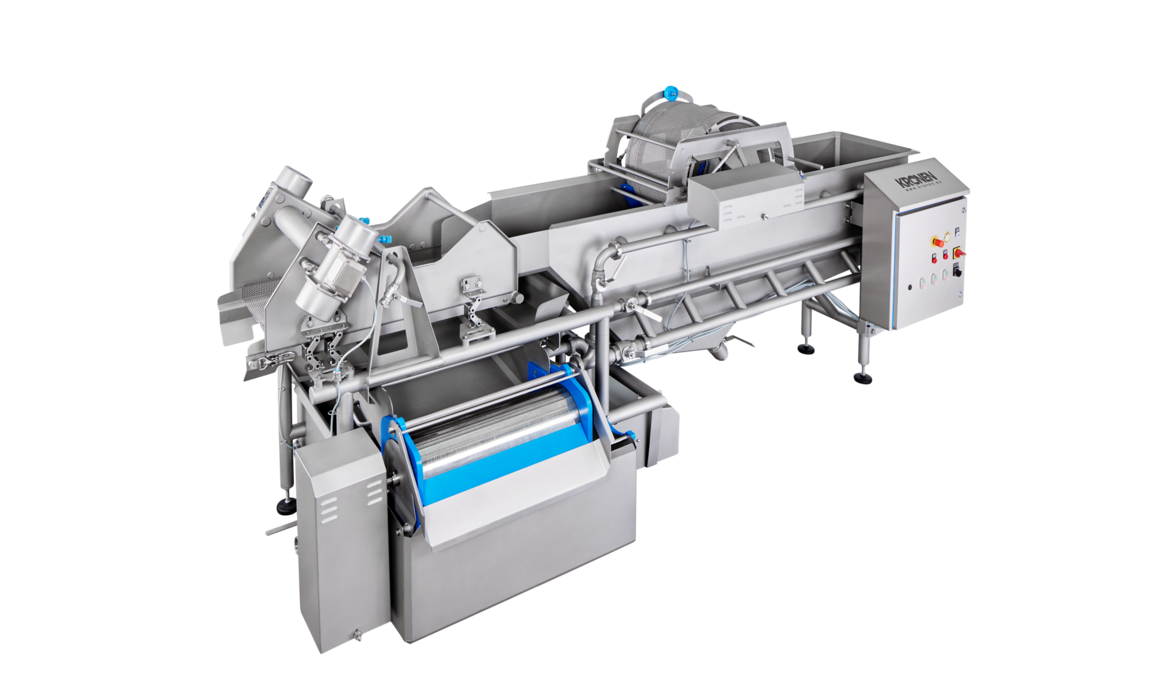

The project involved the development of an innovative washing process for fresh-cut lettuce using non-thermal plasma technology. In this process, plasma-treated wash water (PTW) is used in a newly developed washing machine adapted to serve this precise purpose. The process for the hygienization of the lettuce helps to reduce the risk of packaged cut salads being contaminated with microorganisms.

Efficacy examined in a test phase lasting several months

To prove the efficacy of the process in an industrial setting, tests using PTW to process baby leaf lettuce and other types of lettuce in the HEWA washing machine developed by KRONEN were carried out over several months at the facility of the fresh produce manufacturer Gartenfrisch Jung GmbH. These tests examined the disinfection efficiency in the wash water and on the treated products, resource savings compared to other disinfection methods and the optimization of the products’ suitability for storage and transport.

Optimized in terms of hygiene and cleaning time: the HEWA washing machine

The development of the HEWA washing machine focused on achieving a hygienic design to ensure that the machine has no horizontal surfaces and thus allowing the water to optimally discharge. The washing machine can additionally be fully dismantled for easy and thorough cleaning and is therefore optimized in terms of hygiene and a reduced cleaning time.

A process with a good antimicrobial effect

The use of the HEWA washing machine with plasma-treated wash water (PTW) revealed extremely promising results, with the laboratory examination of the treated lettuce and the water samples providing evidence of a positive antimicrobial effect compared to the washing process using normal tap water. No negative effects of the treatment on the product whatsoever were detected. These results show that the project achieved its objective of developing a resource-conserving washing process using non-thermal plasma technology for disinfecting cut lettuce as gently as possible. The hygienization of the lettuce increases consumer safety by avoiding premature spoilage.

Expertise from research, machine development and the food processing industry

The cooperation between the project partners from the Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB Potsdam), the company Gartenfrisch Jung GmbH and the Leibniz Institute for Plasma Research and Technology (INP Greifswald) with KRONEN, the manufacturer of machines for the food industry, combines expertise and practical knowledge to facilitate the development of innovative, practical solutions to improve food safety. The research project was funded by the German Federal Office for Agriculture and Food (BLE) within the framework of the Innovation Funding program of the German Federal Ministry of Food and Agriculture (BMEL)

Following the completion of the project, the partners will continue to work together to publish the results and make the developed solution ready for the market in terms of industrial use, as well as to clarify issues concerning the classification of PTW as a production resource and its declaration of conformity.

You can find out more about the project here.

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product program of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging. KRONEN additionally offers technical solutions for meat and fish, baked goods, ready meals, dried and frozen products, and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representations in over 80 countries worldwide, and supplies its products to more than 120 nations all over the globe.

With more than 40 years of experience in food technology, KRONEN preserves traditional values such as quality awareness and relies on a sustainable, holistic approach for the hygienic and reliable production of healthy food. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.

You can find a selection of images below (click on the right mouse button and select “Save image as” to download).

Do you require more or other material? We are happy to help! Feel free to contact us here: presse@kronen.eu, T +49 7854 9646-160 / -161.