Automatic, innovative and hygienic: wash, cut or peel fruit, vegetables and salad leaves

At the KRONEN booth at the Anuga FoodTec 2024 trade show, which will take place from March 19 to 22, visitors can again view innovations and new products live and in operation. The HEWA 3800 washing machine, which was launched in 2023, sets new standards in the field of hygienic design and washes salad leaves, vegetables, fruit and other food continuously, effectively and in a resource-saving manner. The avocado robot solution, which will also be demonstrated at the event, pits, halves and peels avocados automatically and as gently as if they were processed by hand.

“Here at KRONEN, we are defined by our commitment to continuously learning, making progress and being innovative. We consider our company to be a think tank for ideas that supplies innovative, made-to-measure solutions to benefit the food processing industry,” declares Stephan Zillgith, Managing Director of KRONEN. “At the Anuga Foodtec, we showcase solutions that incorporate the latest state-of-the-art developments in the areas of hygienic design and automation. For more than 40 years, our close contact with the worlds of industry and research, as well as with groups of experts such as the EHEDG, have been helping us to optimize our solutions based on the latest findings in the fields of technology and hygiene.”

Hygienic washing: based on state-of-the-art developments

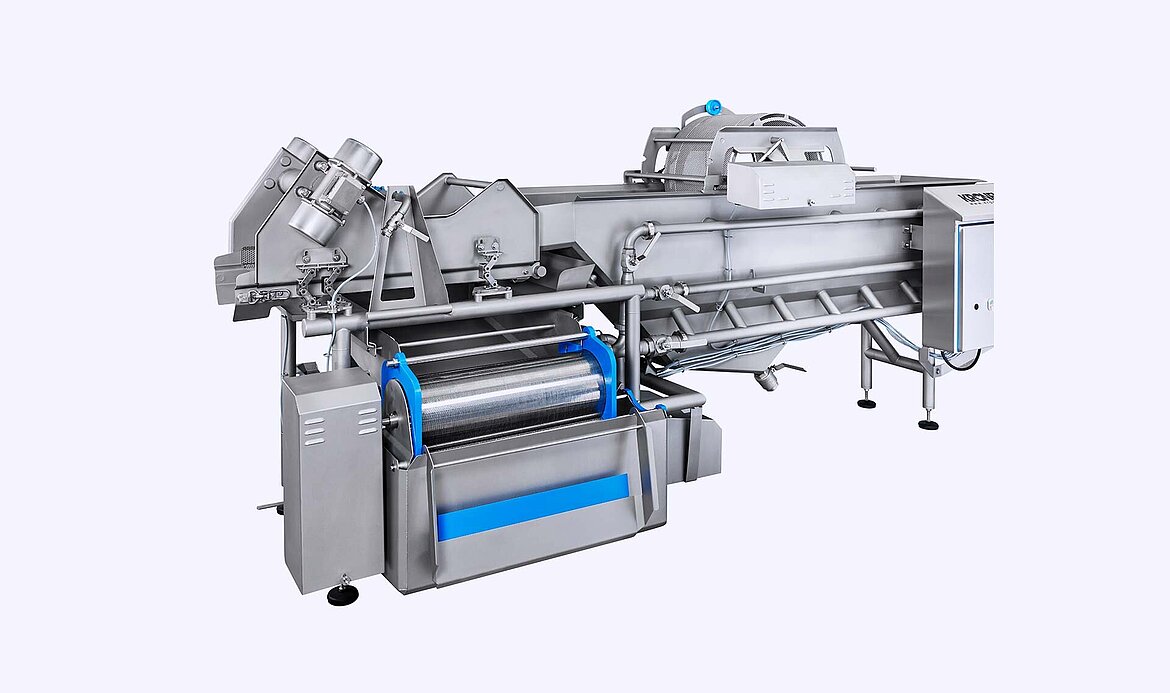

The HEWA 3800 HELICAL washing machine for fruit, vegetables, salad leaves and other foods has been optimized in terms of hygiene and easy cleaning. The design concept also ensures maximum hygiene, for example the fact that the machine has no horizontal surfaces whatsoever, thus allowing the water to optimally discharge. What’s more, all edges are designed to avoid the formation of biofilm. This helps to minimize the risk of contamination and cross-contamination. Effective access to all critical areas of the machine also plays an essential role. The main focus is ensure that the machine can be completely and thoroughly cleaned in a time-saving process. To achieve this, the HEWA 3800 can be fully dismantled.

Like its predecessor model, the GEWA 3800 PLUS, the washing machine can be used for continuous, gentle and effective pre-washing, washing, disinfection, mixing, treatment and rinsing. If it is filled automatically, for example in a processing line, no operating personnel are required. The HEWA 3800 processes up to 2,500 kg of product per hour.

A world first: automatic robot-based avocado processing

KRONEN has developed a special robotics solution for an automated avocado processing line. The line features a solution for the robot-based processing of avocados that is the first of its kind in the world. It can be used to halve, pit and peel avocados both gently and efficiently.

An advantage of this automated solution is the reliability of the robot, which is not impaired even in cold temperature ranges and minimizes the risk of failure. The robot can additionally be easily cleaned and decontaminated, thus enabling maximum hygiene in the processing facility. What’s more, it can also be used – flexibly and as needed – for any length of time and processes a fixed, calculable amount of fruit during operation. The line processes the delicate avocados to produce a visually appealing product comparable to the result achieved when processing avocados by hand.

- The automated processing ensures maximum reliability, hygiene, flexibility and planning in production.

- It guarantees extremely gentle processing and a very high, constant product quality.

- Depending on the desired capacity, the system can be equipped with one to three robots.

- It features integrated tools that were developed especially for processing delicate avocados.

- The solution produces a maximized, constant yield that makes full use of the entire avocado flesh.

- With a cutting machine such as KRONEN’s GS 10-2, avocados can be optionally further processed by cutting them into chunks or slices.

The system features integrated Stäubli robots with specially treated surfaces for optimal cleaning. The system is equipped with remote maintenance technology, allowing users to make the most of rapid, direct support from the KRONEN service team if required.

Up to 1,000 avocados per hour can be processed with three robots. Furthermore, a wide variety of additions can also be introduced to further extend the line. The system can also be adapted for processing various types of fruit in the middle segment as needed.

User-oriented: machines for processing fruit, vegetables and salad leaves

At the Anuga Foodtec trade show in Cologne, Germany, KRONEN will also showcase further new innovations and well-established machines, which it will also demonstrate in full product-processing operation, for example the following products:

- New product: Tona V cutting machine

- New product: MMC manual melon chunk cutter

- GS10-2 belt cutting machine

- KUJ-HC 220 and KUJ-V cube, strip & slice cutting machines

- PL 40K potato peeling machine

- AS 6 and AS 4 apple peeling and cutting machines

- PDS4L pepper coring and dividing machine

- KS-100 Plus lettuce and vegetable spin-dryer

- FLEX M packaging machine

Visit us at the Anuga Foodtec: Hall 10.1, Stand G-008

About KRONEN GmbH

KRONEN is a family-managed globally operating producer and supplier of stand-alone machines, special-purpose machines and high-tech processing facilities for the fresh-cut industry. The product program of KRONEN and its partners covers fruit, vegetable and lettuce processing: from preparing, cutting, washing, drying, dewatering, peeling and sterilizing right through to packaging. KRONEN additionally offers technical solutions for meat and fish, baked goods, ready meals, dried and frozen products, and pet food.

The company, which is based in the German town of Kehl am Rhein and has a second production site in the nearby town of Achern, currently employs more than 130 members of staff, has representatives in over 80 countries worldwide, and supplies its products to more than 120 nations all over the globe.

With more than 40 years of experience in food technology, KRONEN preserves traditional values such as quality awareness and relies on a sustainable, holistic approach for the hygienic and reliable production of healthy food. KRONEN considers itself to be a think tank that provides innovative solutions to benefit its customers and meet all their needs. It guarantees top-quality advice and planning expertise in close cooperation with the industry and research establishments.

You can find a selection of images below (click on the right mouse button and select “Save image as” to download).

Do you require more or other material? We are happy to help! Feel free to contact us here: presse@kronen.eu, T +49 7854 9646-160 / -161.