Who: As an industrial mechanic, Manuel Fehrenbach is the member of our production team responsible for the assembly of special systems and large processing lines. In this role, he assembles machines that have been specially adapted to meet customer requirements or are integrated into larger processing lines – for example two of the machines used by our customer Vitacress for its lettuce processing activities.

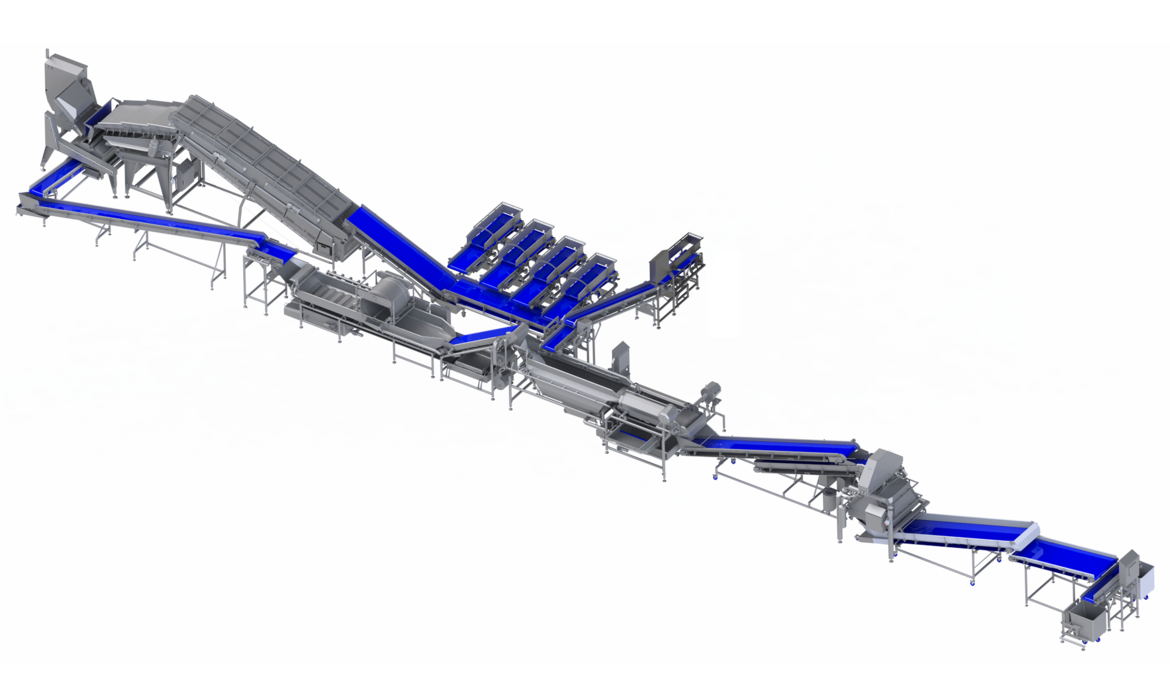

The English supplier of lettuce, herbs and watercress from Andover, has installed four new processing lines from KRONEN. Each of the lines can process up to 2 tons of lettuce and leafy vegetables per hour.

Like: “Being involved in the largest order in our company history to date was very exciting indeed: I visited our customer in England to put lines three and four into operation at the beginning of the year. Both lines began their work in Vitacress’ newly equipped production hall, and it was very interesting to be part of the successful completion of this large-scale project.”

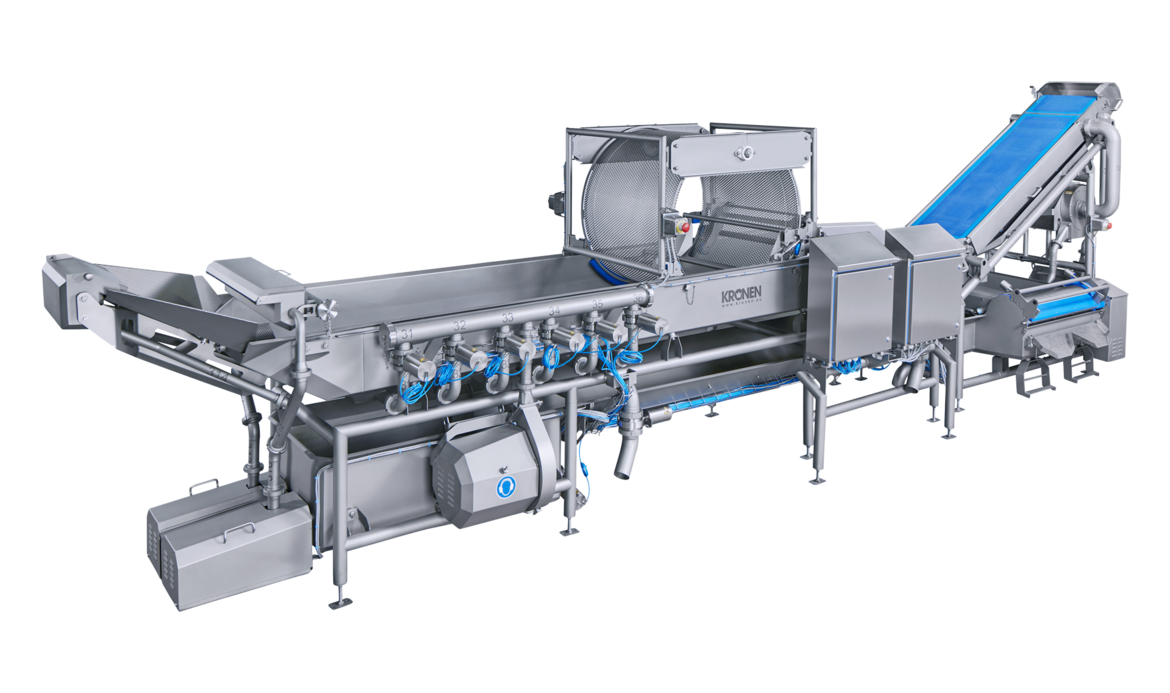

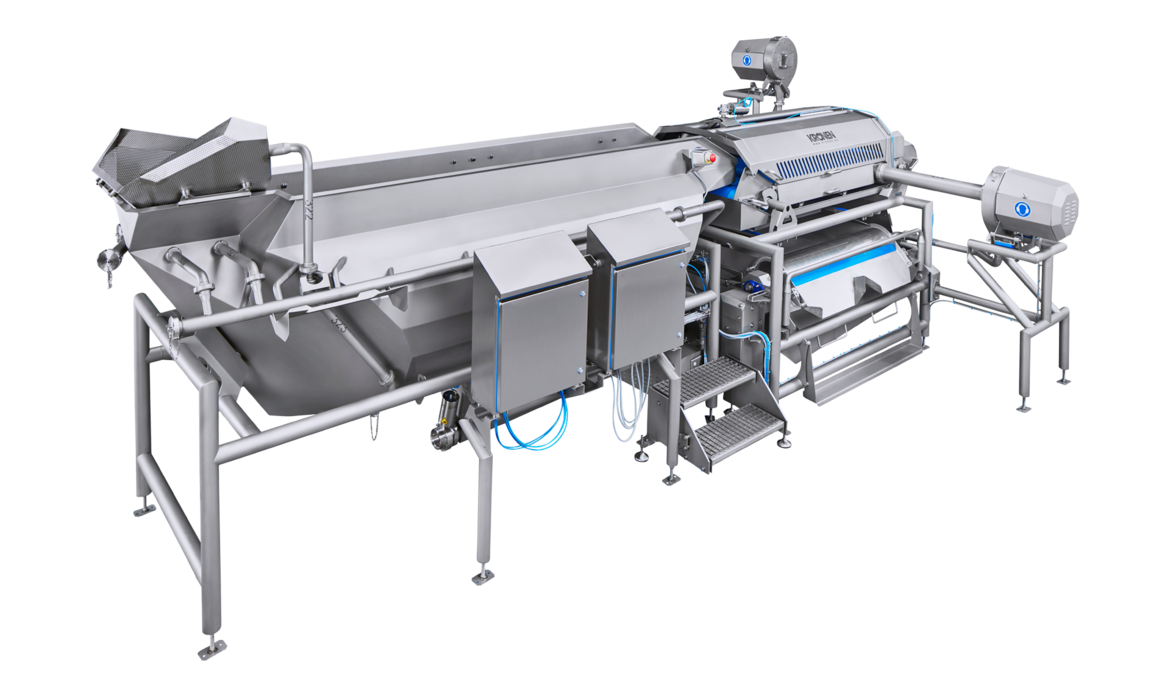

The state-of-the-art, fully automated processing lines are completely networked and designed for the processing of large quantities of delicate lettuce leaves. They contain KRONEN’s GEWA AF pre-washing machines, which were assembled by Manuel Fehrenbach; the GEWA XL HELICAL washing machine; the K850 drying system and additional machines from KRONEN partners.

On his visit to the customer’s facility in England, Fehrenbach was already able to experience the first two lines in operation during the production process live and in person: “With its total of four fully automated processing lines, Vitacress can now process huge amounts of lettuce per hour. Watching the machines we constructed wash and dry such huge quantities of lettuce leaves was truly impressive. I am already looking forward to working on the next projects.”