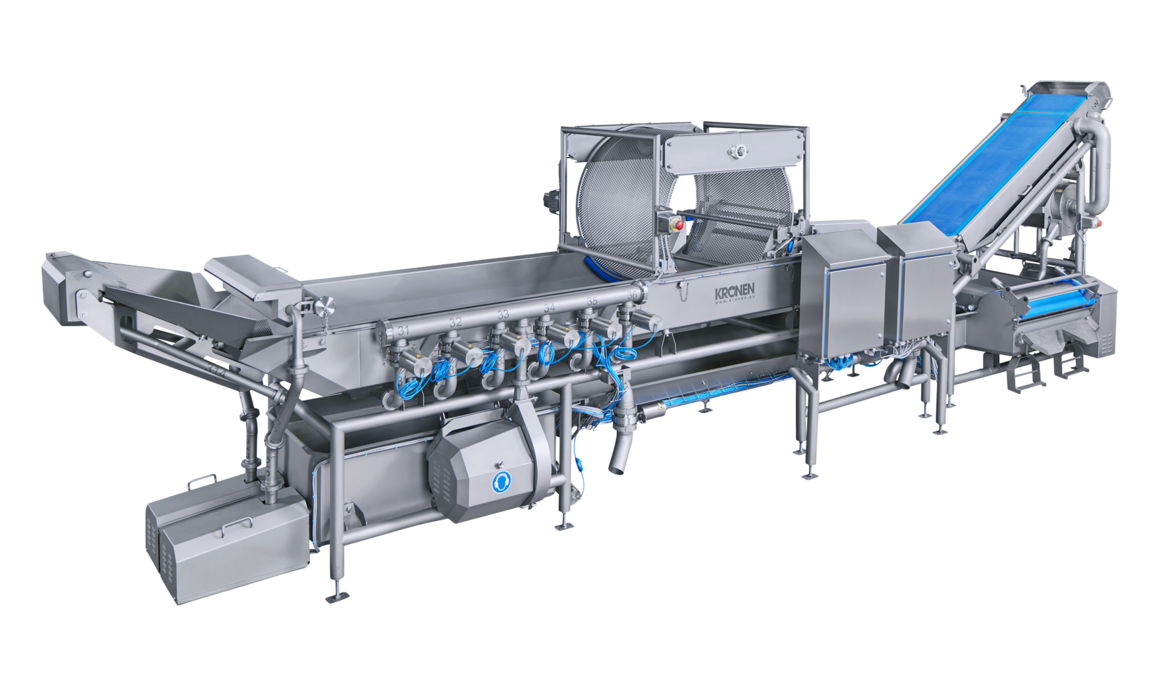

The latest hygiene standards and reduced water consumption: pre-washing of up to 5,000 kg of product per hour

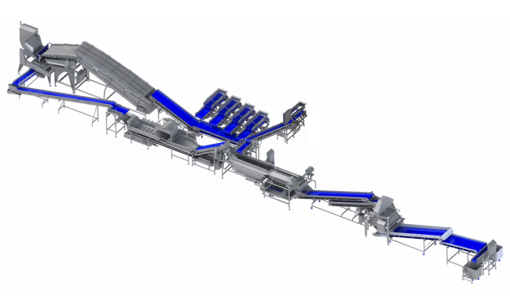

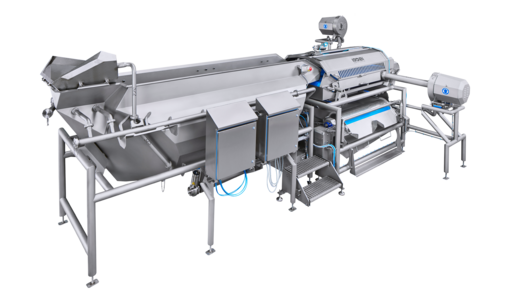

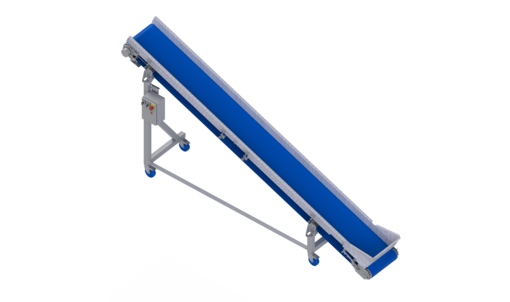

The GEWA AF is used as a pre-washer to remove coarse dirt, sand and stones from light, sensitive products. Due to its method of operation, it is also used to absorb production peaks and therefore make the product flow more continuous. The GEWA AF stands in a processing line downstream from a cutting machine or a weighing system. It takes over the first washing step, which is normally followed by at least one further washing step with a suitable HELICAL washing machine such as theGEWA XL or the GEWA 5000 or GEWA 4000. The capacity depends on the product; for example, 400 to 1,500 kg of baby leaf, up to 3,000 kg of iceberg lettuce or up to 1,000 kg of baby spinach can be processed per hour.

The standard equipment of the GEWA AF includes a highly effective, gentle submergence module, an air module for separating out sand and stones and for loosening contamination, a module with an insect removal drum and a settling module in which sand and stones sink and are regularly flushed out of the machine by means of the sand trap and an automatic valve, while the cleaned product is discharged via the outfeed belt. The side fine particle removal drum continuously filters the water as it runs into the filter tank.

The pre-washer is designed for lettuce, baby leaf and leafy vegetables (whole or cut) as well as floating cut vegetables, such as cabbage and cauliflower or broccoli florets.

The other GEWA washing machines are suitable for non-floating products.