- Votre produit

- Salades, légumes et fruits

- Viande et poisson

- Produits végétaliens

- Produits de boulangerie

- Aliments pour les animaux

- Nos solutions

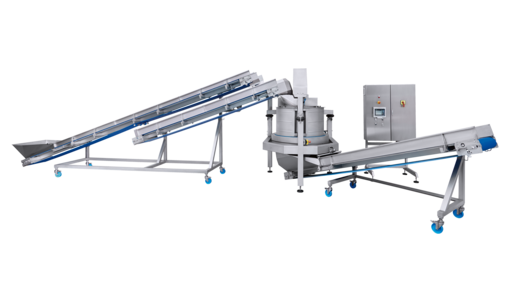

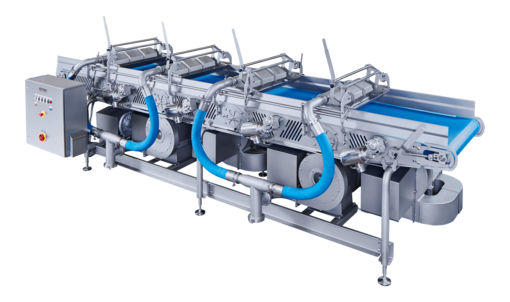

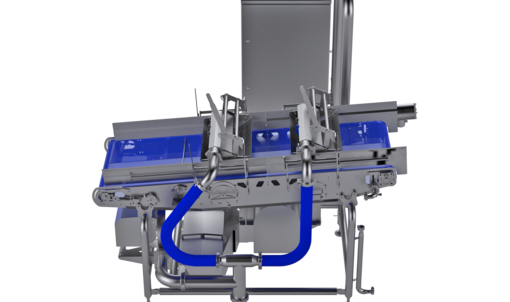

- Machines

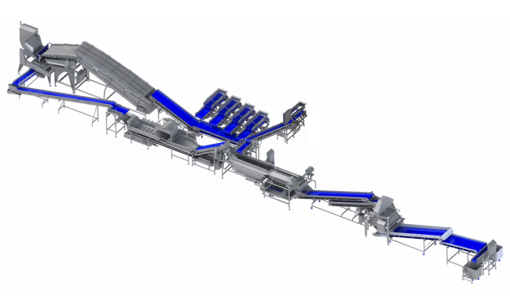

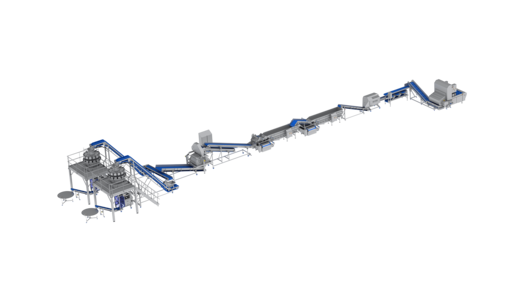

- Chaînes de transformation

- Solutions sur mesure

- Solutions SMART

- L’entreprise

- À propos de KRONEN

-

Carrières

- Carrières

- Votre employeur KRONEN

- Ce que nous offrons

-

Offres d’emploi

- Offres d’emploi

- Électrotechnicien en maintenance industrielle (h/f/d)

- Monteur/technicien de service après-vente (h/f/d)

- Collaborateur grenaillage aux billes de verre (sablage) et assistance à la production (h/f/d)

- Opérateur en usinage (h/f/d) pour notre usine d’Achern

- Mécanicien de construction (h/f/d)

- Soudeur TIG (h/f/d) sur tôlerie

- Mécanicien industriel (h/f/d) dans le montage

- Assistant à temps partiel (h/f/d) dans le marketing, le marketing en ligne, le marketing digital et l’événementiel

- Apprentissage et formation en alternance

- Engagement

-

Témoignages

- Témoignages

- Daily Food Co., Arabie Saoudite

- GROUPE VOIE VERTE, France

- Centre de transformation Sodexo, Espagne

- Chaîne de transformation de salades, Mexique

- Foodlink, États-Unis

- Fabrication de kimchi, Allemagne

- Zalat-o-mat GmbH, Allemagne

- Wolf Wurstspezialitäten GmbH, Allemagne

- COTO C.I.C.S.A., Argentine

- Bortar Group, Turquie

- Verdeagua, Uruguay

- Postuma AGF, Pays-Bas

- Grönsakshallen, Suède

- LENTA, Russie

- Adam Theis GmbH, Allemagne

- Kanes Food, Grande-Bretagne

- Compagnies aériennes, de croisière et cuisines centrales

- Recherche

- Hygiène et qualité

- Sites

Fermer la navigation latérale